An Integrated Tunnel Monitoring System (ITMS) with multi-sensor automation is indeed a robust solution for high-precision, real-time measurement of structural changes in tunnels. This approach replaces manual, static, and discrete measurements with a continuous, automated, and full-section monitoring system, ensuring safety during both construction and operational phases.

Multi-Sensor Network:

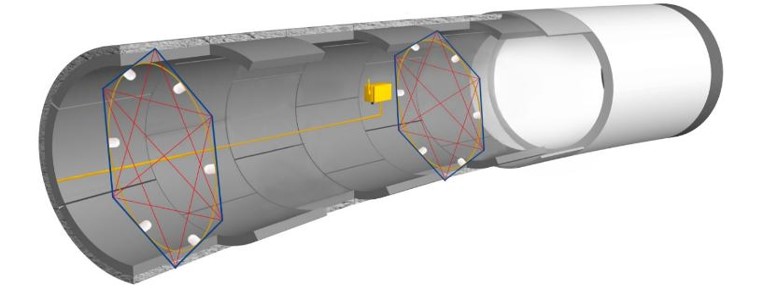

- Convergence/Divergence Sensors (Tilt and Optical Displacement Laser Distance Meters) → Detect radial deformation.

- Tiltmeters & Inclinometers → Monitor settlement and inclination.

- Pressure Cells → Measure stress on tunnel linings.

- Strain Gauges → Detect deformations in reinforcement.

- Extensometers → Monitor rock/soil movement around the tunnel.

- Total Stations → Full-section 3D deformation mapping.

Automated Data Acquisition & Processing:

- Real-time data logging via Vibrating Wire Wireless-enabled sensors.

- Automated routines for convergence calculations, tilt analysis, and stress-strain correlation.

- Edge computing for immediate anomaly detection.

By integrating automated multi-sensor monitoring, tunnel safety shifts from reactive to proactive, ensuring high precision, efficiency, and operational safety throughout the lifecycle of the structure. This system is particularly crucial for urban tunnels, TBMs, and deep excavations where real-time structural feedback is essential.